Products

MOULD TUBES

MOULD PLATES

MOULD-COOLING JACKETS

ENGINEERING

The copper mould is one of the most important components of a continuous casting machine.

Whilst giving the desired shape to the steel in production it should ensure the optimal skin growth in order to contain the liquid steel during the solidification

process, therefore avoiding internal or superficial defects.

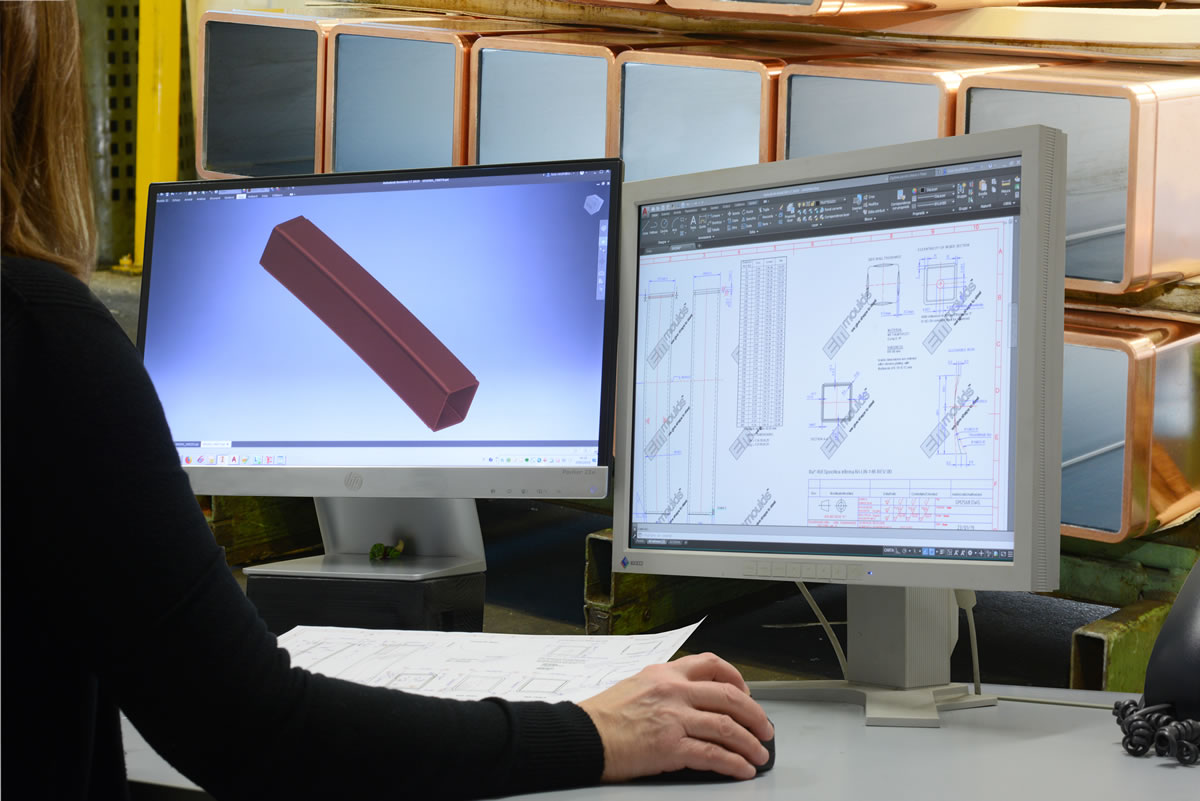

It is extremely important to design the mould considering all variables and casting practices that may affect the steel production and quality.

With more than 50 years of experience in the field, EM MOULDS is able to design the most suitable solution for each plant.

Every mould design is based on computer aided analyses and simulations – which enable the study of the thermal heat exchange and the steel solidification along the mould – as well as on site trials results.. This tailor made approach to suit he required productivity and steel quality is key to EM MOULDS success worldwide.

EM MOULDS

MANUFACTURING

M MOULDS tubular and plate moulds are produced at the Fornaci di Barga plant.

This fully integrated plant includes copper melting and casting, extruding, hot and cold rolling, drawing, machining, heat treating and electrolytic coating.

The complete production process control allows EM MOULDS to guarantee the full product traceability and high flexibility to meet every Customer’s demand both in terms of quality and delivery time.

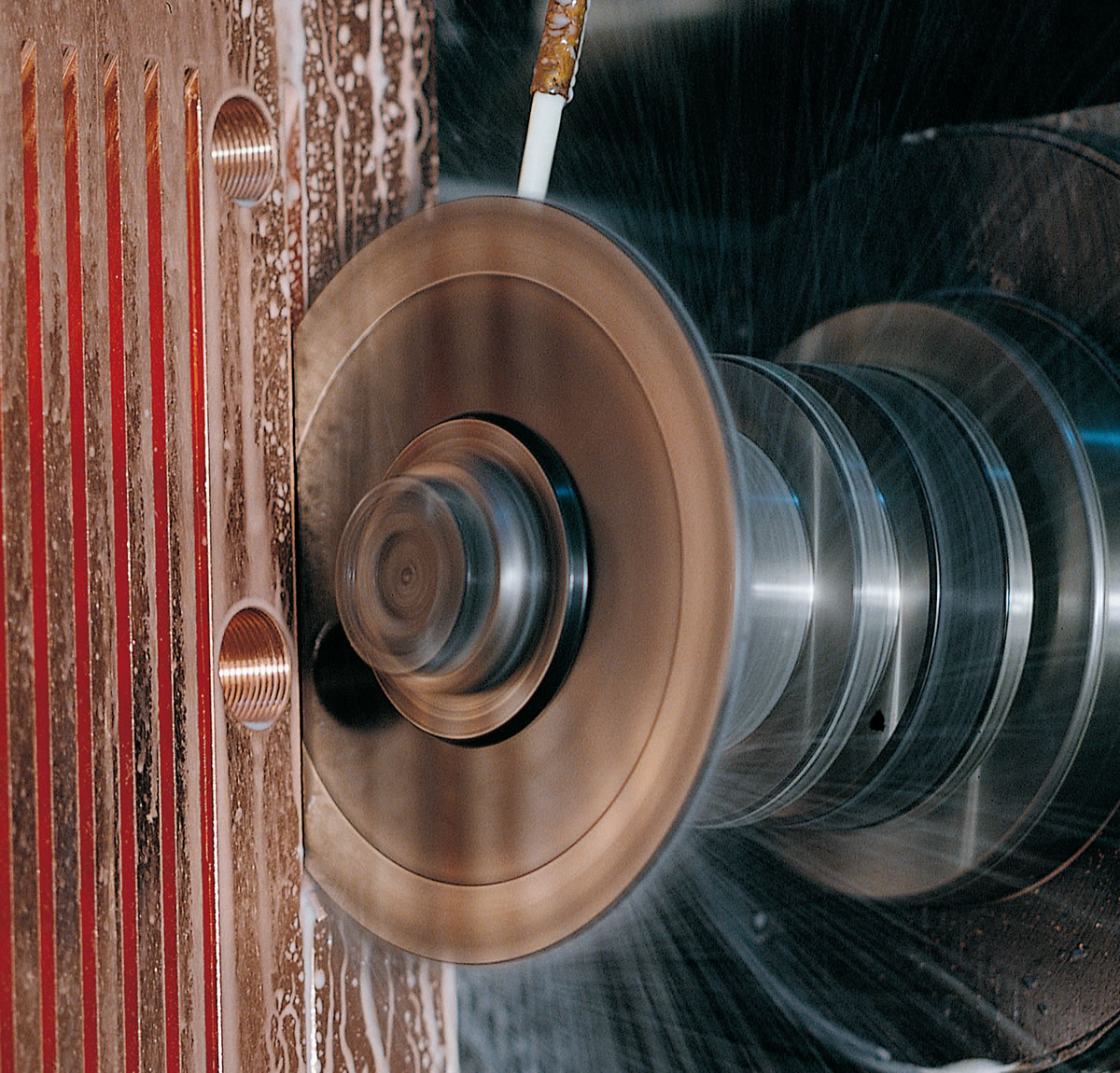

The production process for tubular moulds begins with the casting of round bars. These are subsequently hot extruded or forged. The extruded tube is then cold-drawn and formed to attain the geometrical and mechanical features required by the technical specifications, which of course also includes taper. Tapering is achieved through special steel tools, which are specific to each mould tube and are also manufactured internally through CAD/CAM technology.

Finally, the tube undergoes machining and is then chromium-plated internally, before being inspected and measured.

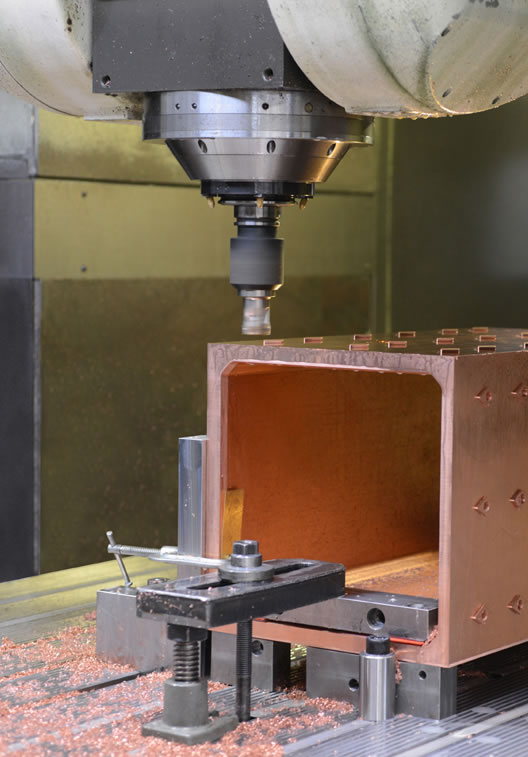

Production of plate moulds starts with the casting of a copper slab which is then hot rolled (or forged) and subsequently cold rolled.

The next phase is a fully ultrasonic inspection, after which the plate can be machined to achieve the final design. During this phase slots for thermocouples

and plate fastening are also manufactured in the required configuration.

The last production phase consists of mould plate coating.

EM MOULDS

Quality Assurance

EM MOULDS is fully committed to guaranteeing the quality standards of its products and processes.

After every production step the products are inspected and measured. All data is reported in the certificates forwarded to the Customers together with the moulds.